How To: Install Boost and Air Fuel Gauges in a Turbocharged Car

- 5 minutes read - 943 wordsToday I’m going to install these AEM gauges in my turbo Honda CR-V so I can monitor air pressure in the turbo system and the air/fuel ratio going into my engine.

First, a little unboxing. What do you get from AEM for $360? The air fuel wideband gauge comes with alternate faces so you can match them to your factory gauges. It also includes two wiring harnesses and an o2 sensor (not pictured). You also get an adapter ring for the o2 sensor that I won’t need for this car.

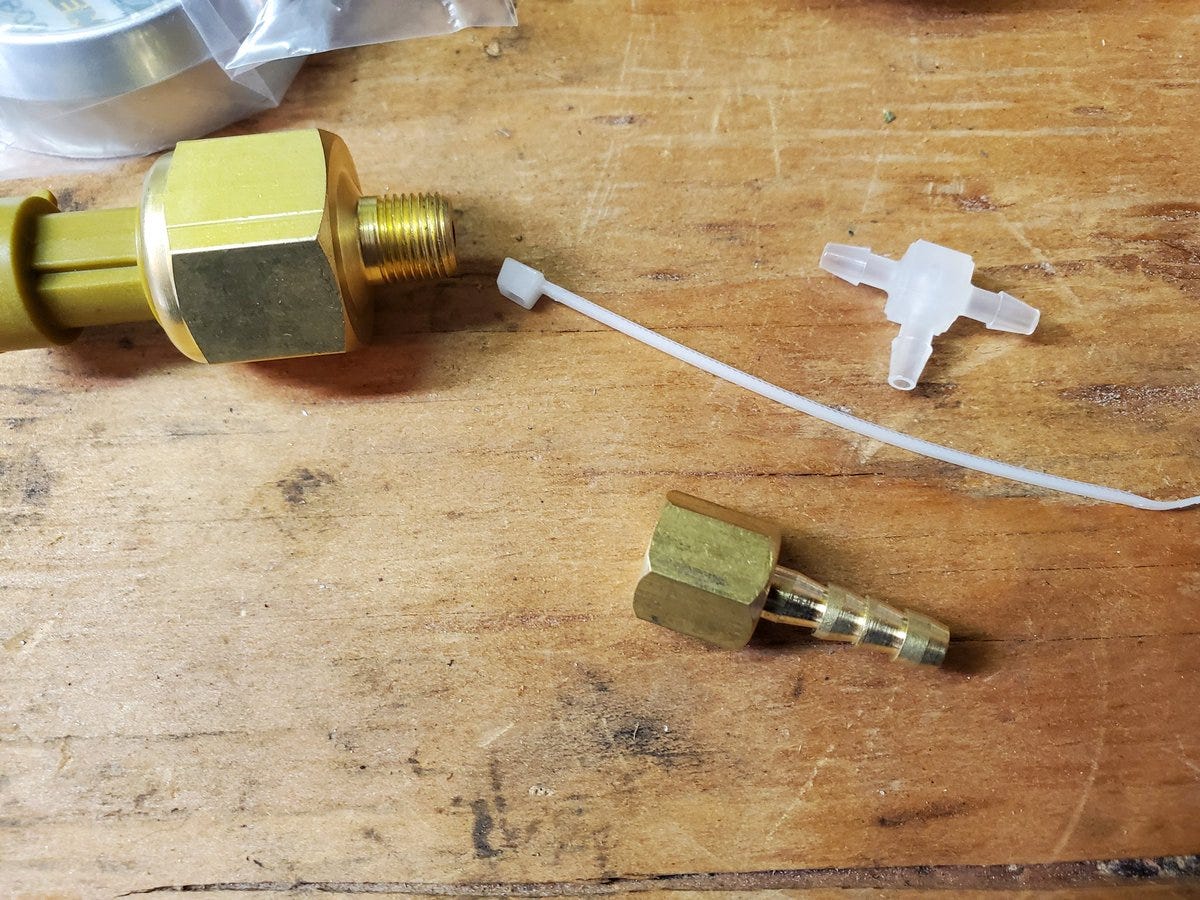

The boost gauge comes with 2 more harnesses, a very short vacuum line, some air fittings, alternate face and another sticker just to make sure people know you’re using name brand parts.

These gauges both require getting some sort of data from the engine bay into the cabin of the vehicle. I’m going to begin with the parts that go in the engine bay. First, I’ll install the o2 sensor which is needed by the air/fuel wideband. I need to remove this plug from the exhaust downpipe

This o2 sensor is going to calculate what the air/fuel ratio was during combustion by measuring what is left over.

And tighten it down with a 22mm wrench. This is where I would have used that adapter that came with the kit if the bung hadn’t been the same size as the sensor.

Now I’ll drop down the harness that the sensor will need to plug into. I’m being very careful to give it a path that avoids parts that move or get hot like axles and exhaust pipes.

Here’s where the harness meets the sensor. I’ll need a lot of zip ties to keep the wiring away from that axle.

Before I run the o2 sensor harness into the cabin I’m going to connect the parts the boost gauge needs in the bay. This pressure sender unit needs to be connected to my existing vacuum system so that the boost gauge can calculate air pressure.

They included an adapter for the presser sending unit so I can connect the vacuum line, a T fitting, and a single zip tie. Cute.

If you read my CR-V turbo guide you’re no stranger to tapping into vacuum lines. I’ll add this T here in-line with the cruise control unit.

Here’s the T installed and plumbed to the pressure sender. I’m a little disappointed that a kit at this price didn’t include a bracket and some self tapping screws but I guess I’ll just zip tie the brass unit to the factory wiring.

Now that I have my data sources installed in the engine bay it’s time to pry up this rubber plug so I can pass the wires into the cabin.

And a lot of this dash is going to need to come apart.

That was… Surprisingly easy

After lots of contorting my body under the dash and I have passed the cables from the engine bay into the cabin.

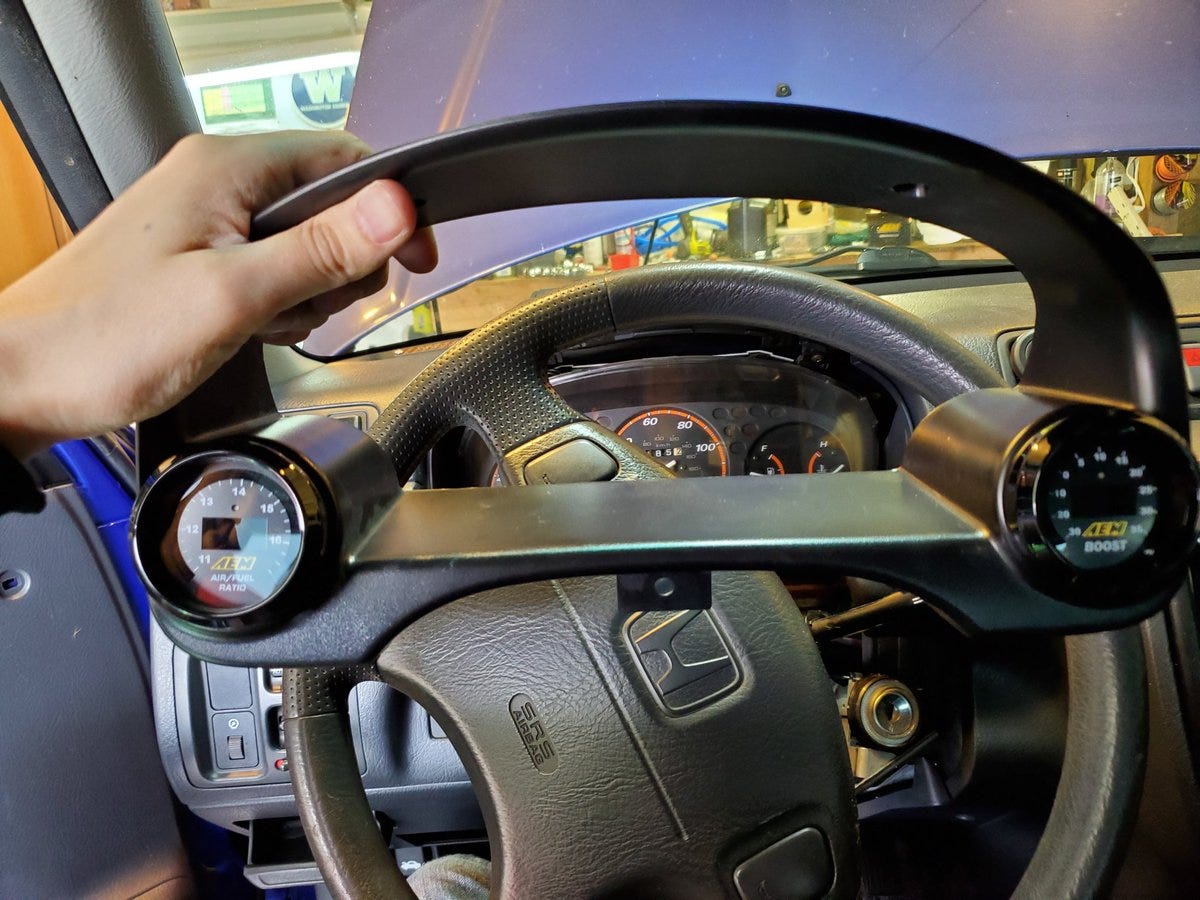

Now as far as actually mounting the gauges I have 2 choices. I have a pillar pod that doesn’t fit well at all and doesn’t match the interior and I have a surround for the factory gauges that also doesn’t fit. They were intended for an Integra and Civic respectively — no one makes CR-V specific turbo parts…

They look really clean in this surround and are less of a thief magnet this way so I’m going to try to brute force this with double sided tape, zip ties, screws, whatever it takes.

After more careful snaking of wires and zip typing I have fed the harness ends up to where the gauges will be. Neat!

It’s important to note that although I’ve connected the signal inputs to the gauges I haven’t done anything about power and ground yet. Let’s do that next.

Using this light tester I’ve identified a blank spot on my fuse box that only has power when the ignition is on. This is important because I don’t want the gauges to stay lit up when the car is off. If you don’t have a light tester I highly recommend adding one to your tool kit ASAP. If you buy one through this sponsored link I’ll get like 50 cents or something.

You can do electrical with just a razor blade and pliers but here’s the tools I’ll be using: a crimper, a self-adjusting wire stripper, snips and a Freedom knife.

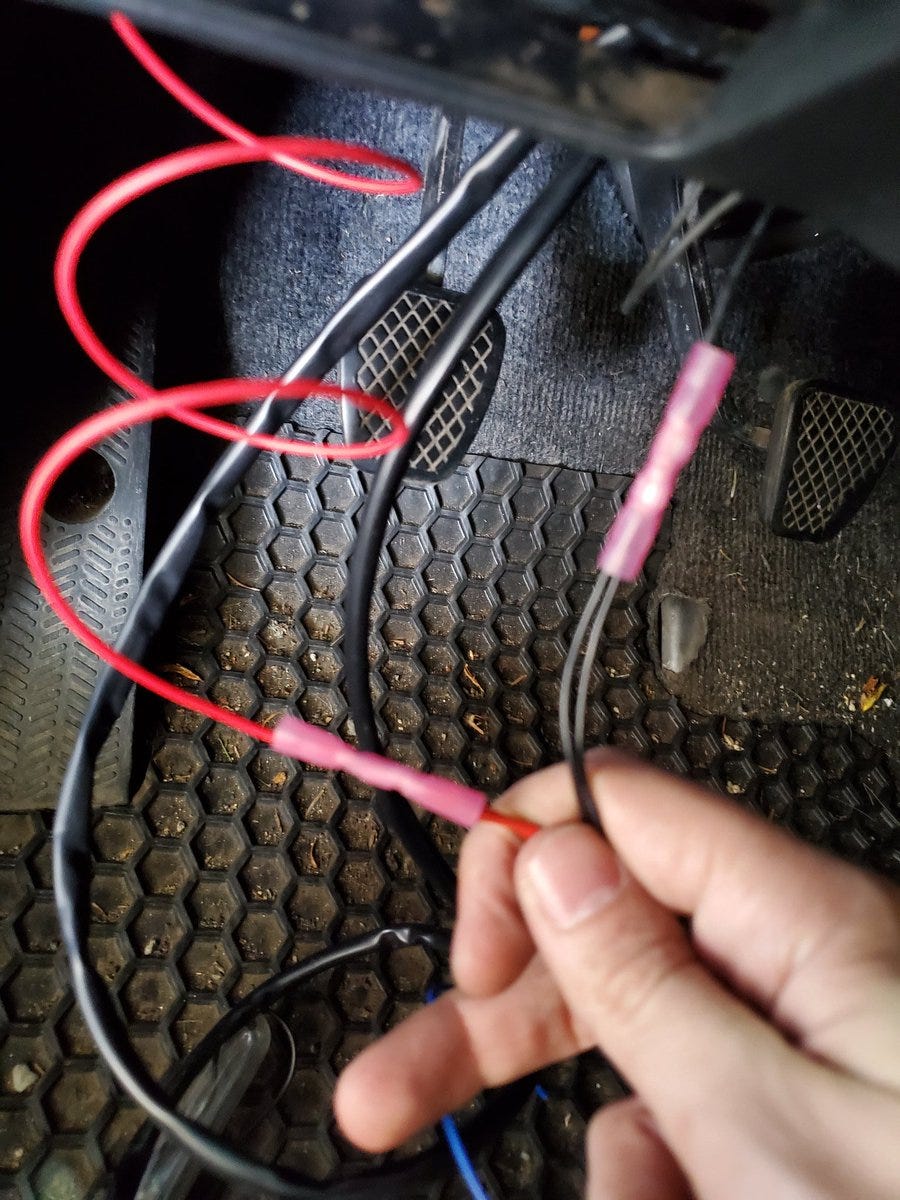

I combined the power and grounds for the two gauges together for simpler splicing into the car. The blue and white coming from the boost gauge are for a boost controller which I don’t have and the white from the air/fuel gauge will be going to the ECU.

I tapped the power into the fuse box with a 7.5A fuse and found a 10mm bolt behind the ignition to ground to.

So let’s put the plastic back on and fire them up!

Cool! They work.

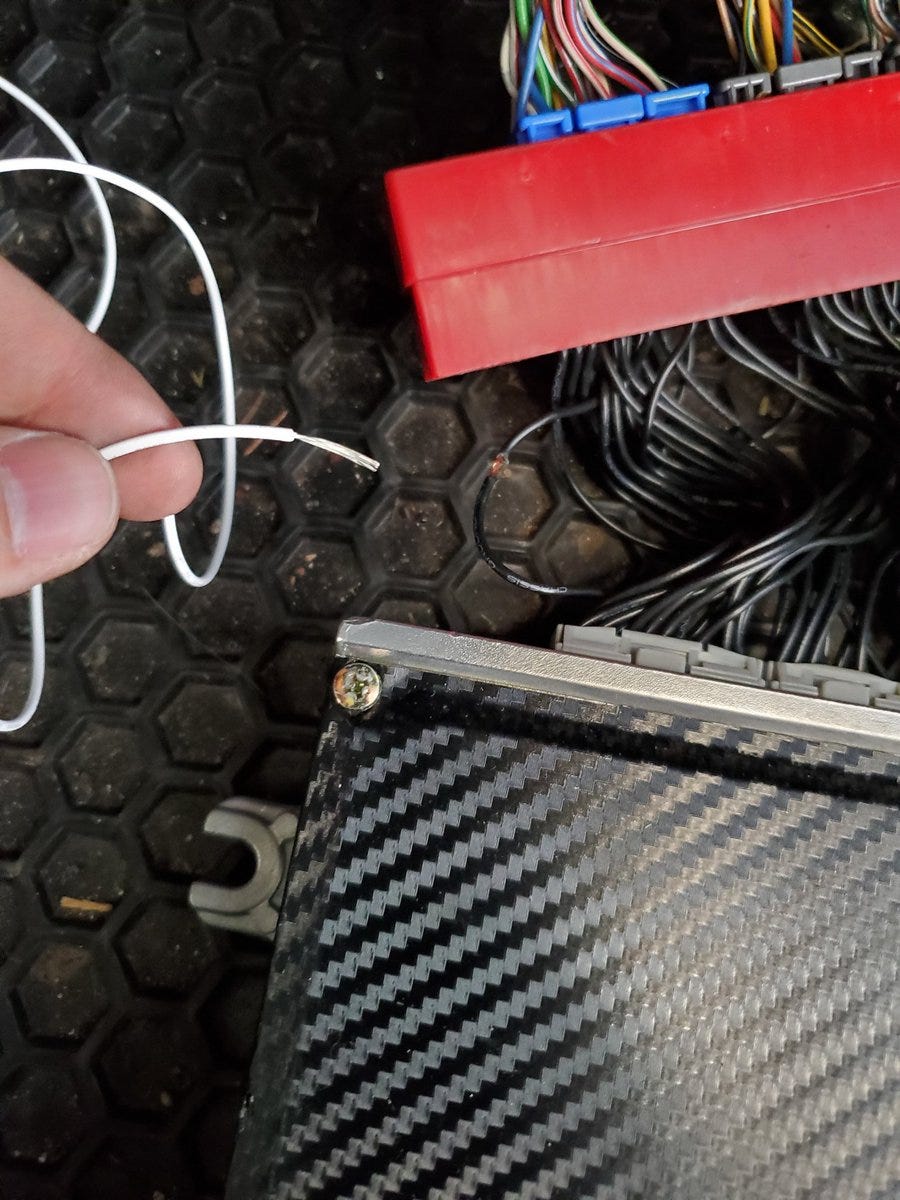

We could call this “done” except I want to take that data I’m getting back from the o2 sensor and send it to the ECU so it can actively improve the air/fuel ratio. I’ve extended the white wire from the air/fuel wideband so it can go over to the ECU on the passenger side. Here’s my engine computer with the wire I need to tap into already partially bared.

I soldered that in and wrapped it in tape. All I need to do is tuck the ECU back behind the kick panel and I’m done!

Now I can cruise around and admire my AEM gauges while obsessing over what the optimal air/fuel ratio should be anyway?

Thanks for reading!