Let's Fabricate a Turbo Wastegate Dump Tube

- 4 minutes read - 652 wordsThis is the third post about my turbo CR-V. The can read about the original build and installing boost and air/fuel gauges.

Today I’ll be doing some metal fabrication to add a “dump tube” to the CRV’s turbo wastegate. This is my first project with my new welder. You can read about the welder setup here.

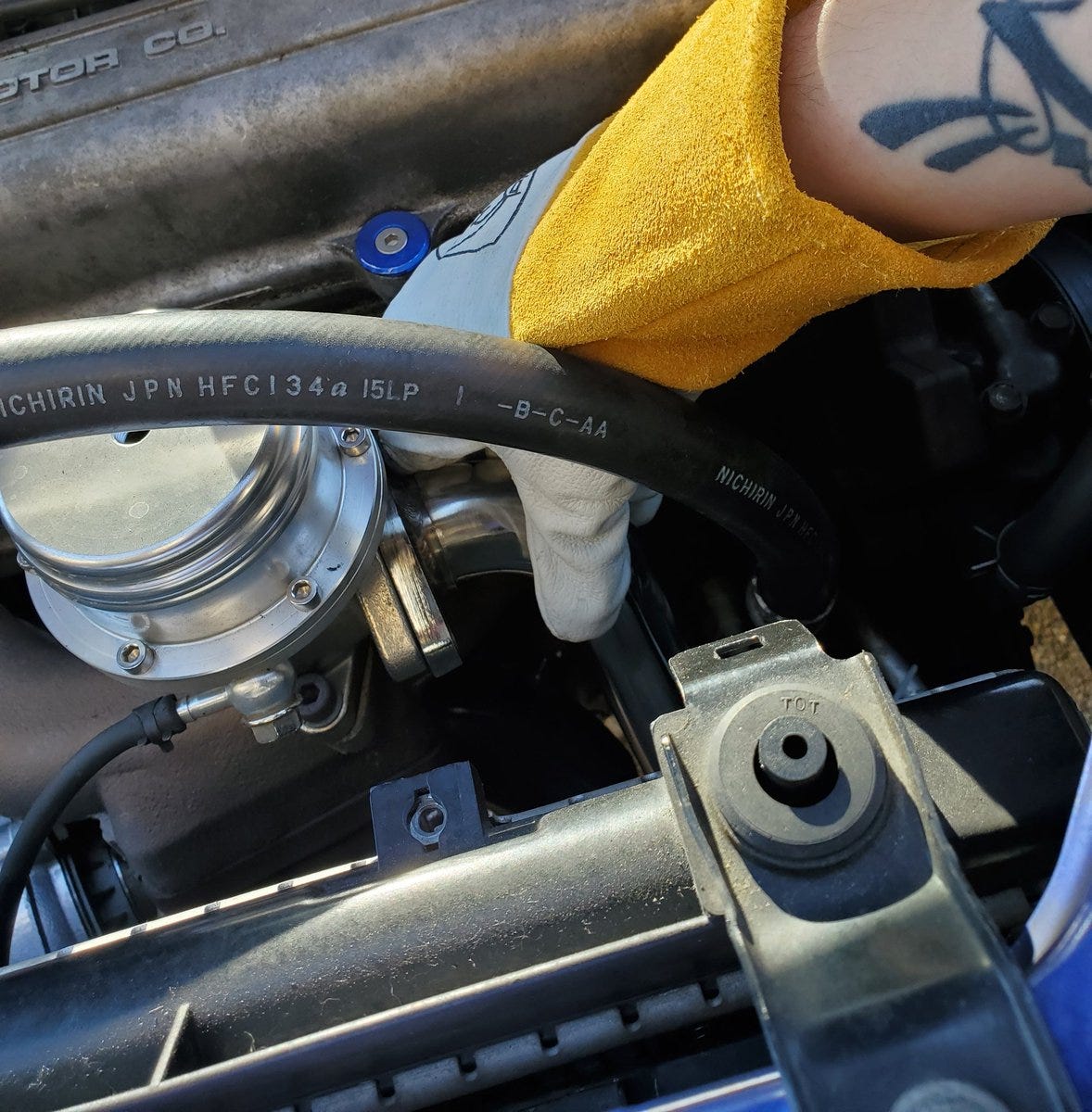

This silver thing I’m touching is the wastegate in the CR-V.

When I’m in boost and I exceed 10 psi the spring inside compresses and releases hot exhaust gas through this 1.5" hole (instead of using that gas to further spin the turbo turbine wheel).

It works just fine and it keeps me from blowing up my engine but it also happens to literally breath fire all over my air conditioner and power steering assemblies. They’re more than a little sooty.

The plan is to take this 1.5" stainless steel tube that has a 2 bolt flange (that mates up to my wastegate) and this other tube and make a dump tube that will direct the gases down and away from any vital components.

First I need to cut the flange off because the angle the tube is on it now runs right into the exhaust manifold. I’ll weld it back on later at a different rotation.

As usual, my weapon of choice for cutting steel is this Ryobi angle grinder with cutting wheel. By the way, any links to tools in my posts are sponsored links and I may earn a commission if you buy them.

Once I have the flange off I’ll smooth out the rough edges with this Ryobi 6" bench grinder.

Now I can hold the tube and flange onto the wastegate and roughly see the angle I’ll need to weld it back together at later.

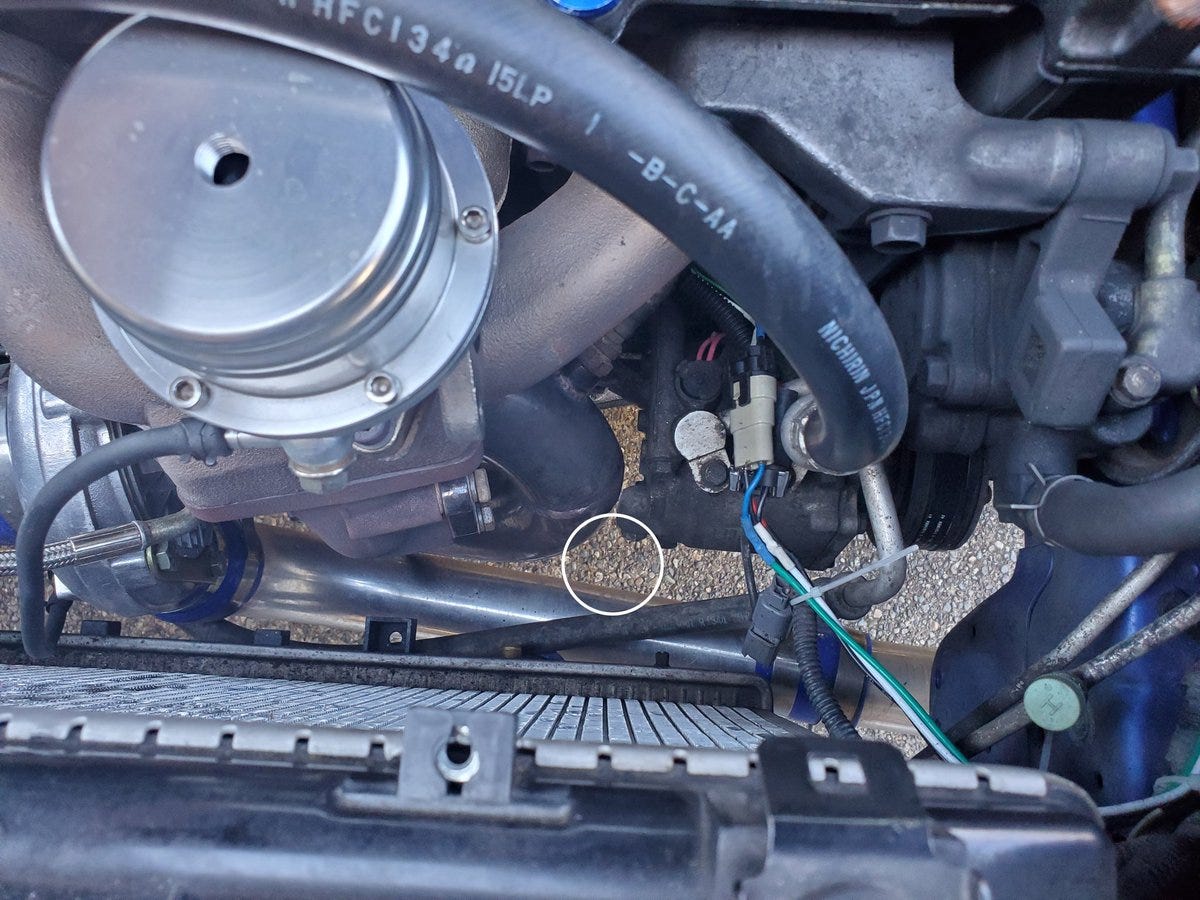

That’s not the only angle I have to consider. I need to extend this tube down past the AC compressor and thread the needle between the intercooler pipe and the exhaust down pipe. The target is the white circle so that I shoot fire down at the pavement.

I stuck my arms down there and held this paper towel tube at the angle I need on the end of this steel tube while my son taped it.

Now I can mark on this steel tube where to cut to recreate the angle from the paper towel tube

More cutting and grinding… My neighbor came by to remind me that if I just bought a “real” car I wouldn’t need to do stuff like this every weekend. He doesn’t understand me at all.

It’s coming together.

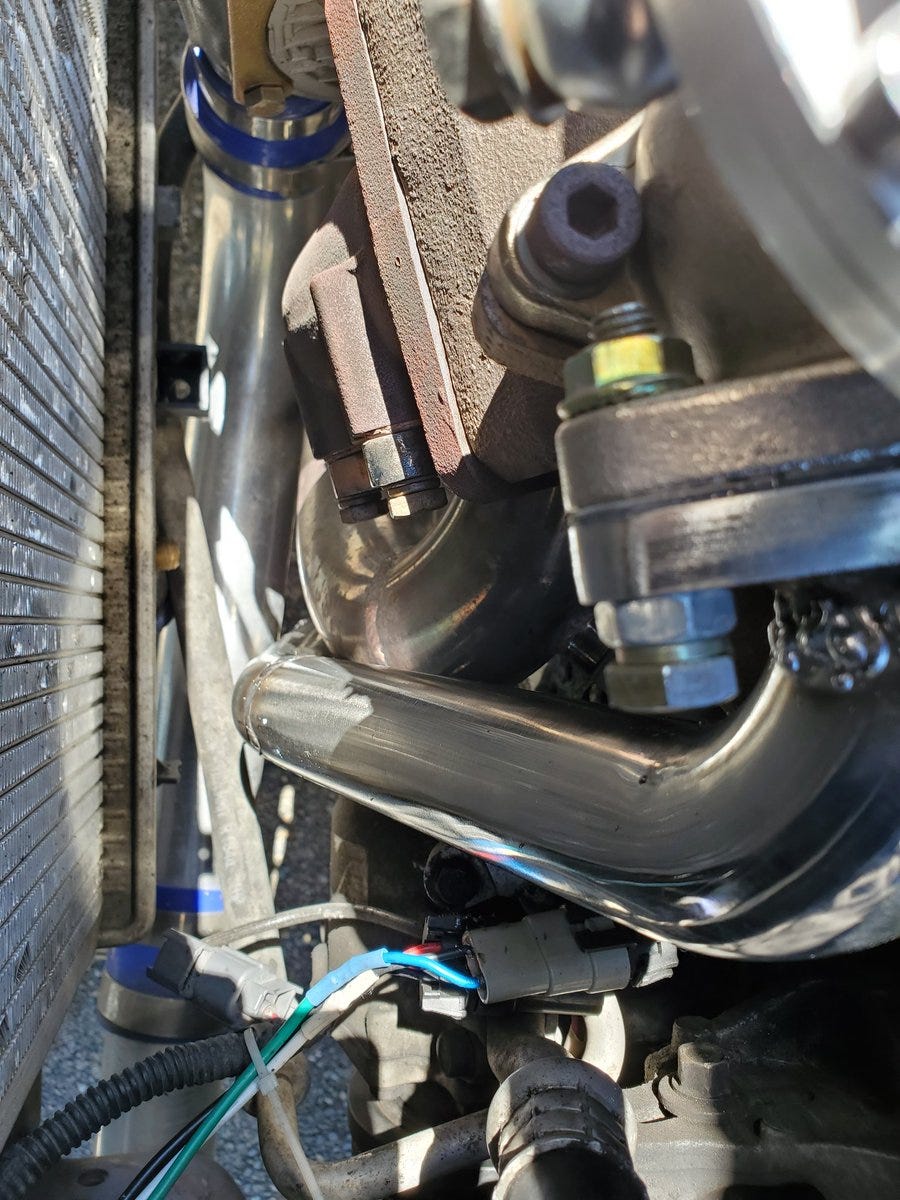

I held all the cut pieces in the engine bay and this angle wasn’t exactly right so I cut this sliver off to correct it.

I held the pieces in place again while my girlfriend marked with a sharpie so I know where to weld it. (My son had wandered off by this point).

Now for the fun part.

I only got a welder last week and this is my first try welding a curve. It’s not pretty but it will hold. Perhaps I should have sanded this coating off first? This is also my first time welding stainless.

The welds are not perfect but I’m pretty pleased that the angles are all correct to follow the route and not hit any other components under the hood.

One last thing I want to do is add a little hook away from the intercooler pipe at the end

This should be good

Tried a different technique… Still learning.

Looks a little better after some wire wheel action

It’s ready for install.

Here it is installed. If you recall the original goal was to go down and around the exhaust down-pipe, air conditioner and intercooler pipe without touching any of them, which I succeeded in.

And here is where it exits blowing hot gaseous fireballs away from everything important

Thanks for reading! 👋