Unboxing and Setting Up a MIG Welder

- 4 minutes read - 750 wordsI’ve wanted to learn to weld for years and I finally pulled the trigger on a MIG welder. I picked the WeldPro MIG155Gsv. I knew I wanted a MIG and I wanted something that could run on ~110v and ~220v. This was only $300 and good reviews. Let’s see what’s in the box.

A good sign that you didn’t open the box upside down is when the first thing you see is the paperwork.

The first box has all these accessories

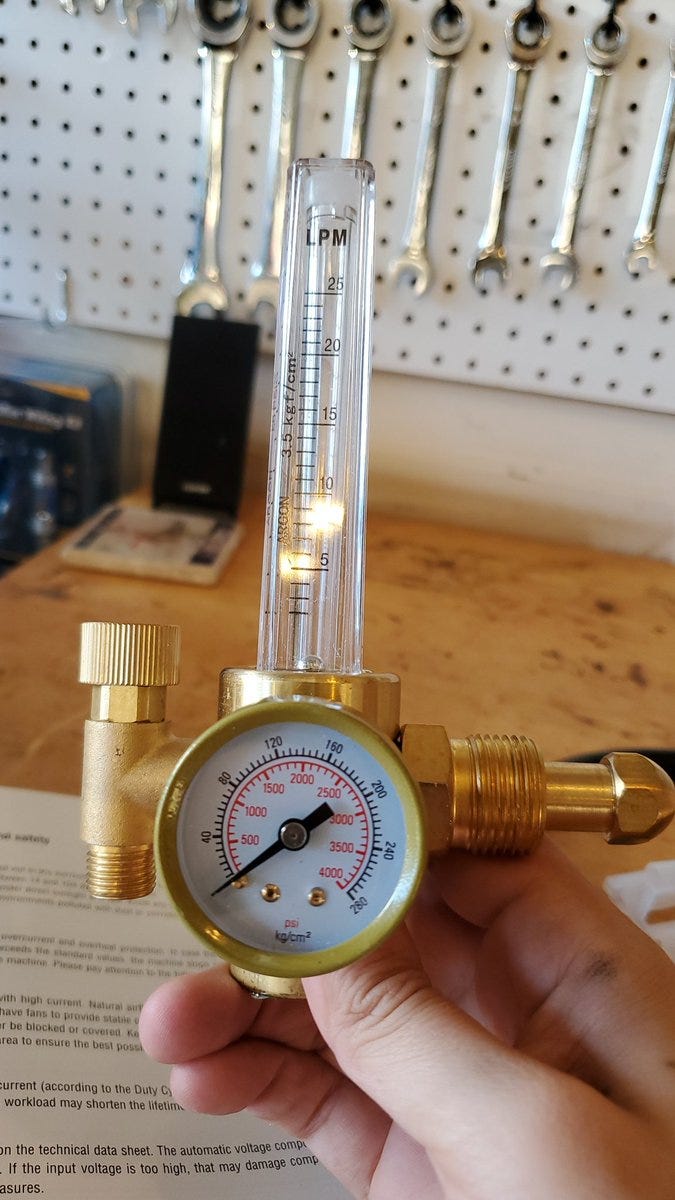

This gas gauge is pretty neat

The welder has a 220v plug on it but it comes with a handy adapter for 110v.

More brass on this gas line.

Pretty nice ground clamp and electrode holder. I don’t plan to do much stick welding but should I want to, I can.

It comes with what I think are torch tips and some other hardware I don’t know the purpose of (yet).

Next up is the welder itself complete with forbidden salt packets.

Build quality feels nice. The controls feel nice too.

I had to wait 10 days for this welder to arrive so I had time to stock up on accessories, like this sweet cart.

I hear gloves are important. I got some thick heavy ones and some thinner more nimble ones.

To hold the work pieces I want to weld I also got some specialized vice grips and sets of magnets. These will be important for holding things together that I want to weld.

And some welding pliers and a wire brush! I have no prior welding experience so I’ll probably need to clean off some slag when I get started.

Lastly, I have .030 and .020 MIG welding wire and this sweet chipping hammer for more stubborn slag.

And of course this hefty tank of 75% argon and 25% carbon dioxide from a local welding shop. This cost almost as much as the welder…

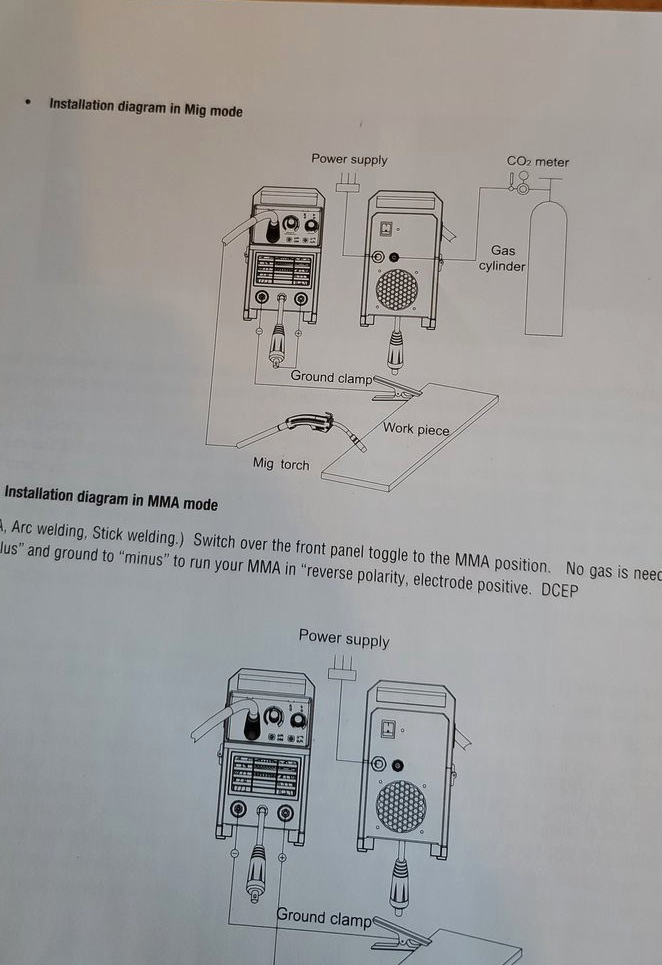

Let’s set this up in MIG mode since I went to the trouble and expense of getting that tank.

In MIG mode you plug the machine into its own positive socket. For arc welding I would plug the electrode holder in there.

The ground clamp goes into the negative socket. These sockets aren’t threaded but instead are notched which is actually kind of nice. You plug in the male end and then turn it 180 degrees to lock it in place.

Now I’ll plug the gas line into the back. That nut is 17mm. Nice.

It came with a small adapter piece to join the gas line and the gauge. Those nuts are 19mm and 17mm. I only work on Japanese cars so using metric here is convenient.

This safety cap didn’t want to unscrew. I used a couple taps from a hammer to motivate it.

Maybe it wasn’t metric after all. This next nut is neither 24mm nor 26mm but in fact 1".

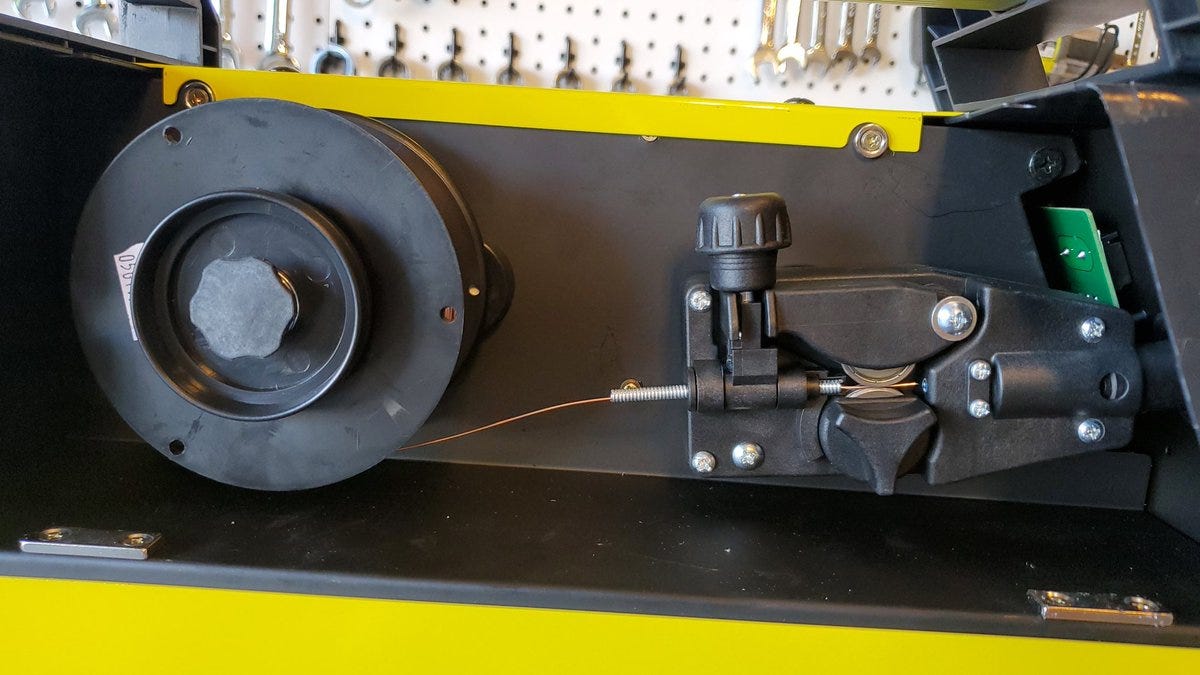

This side panel comes off to reveal where the wire goes. It reminds me a lot of my 3D printer. This panel is held on with magnets which is a nice touch. It’s very easy to remove and reattach.

The instructions say the spool should feed from the bottom. Remember those various wheels in that little bag? They go here to feed the wire to the torch hose. There are different wheels for different thickness wire.

Now I’m opening the tank valve and plugging in the welder. I’ll take this opportunity to remind you that I have never welded, don’t have anyone here teaching me and I’m just reading the manual. 😳

With the machine on I’ve adjusted my tank flow to 20 liters per minute (as the manual says to do).

After adjusting the feed tensioner I’ve allowed the welder to feed the wire through to the end of the torch.

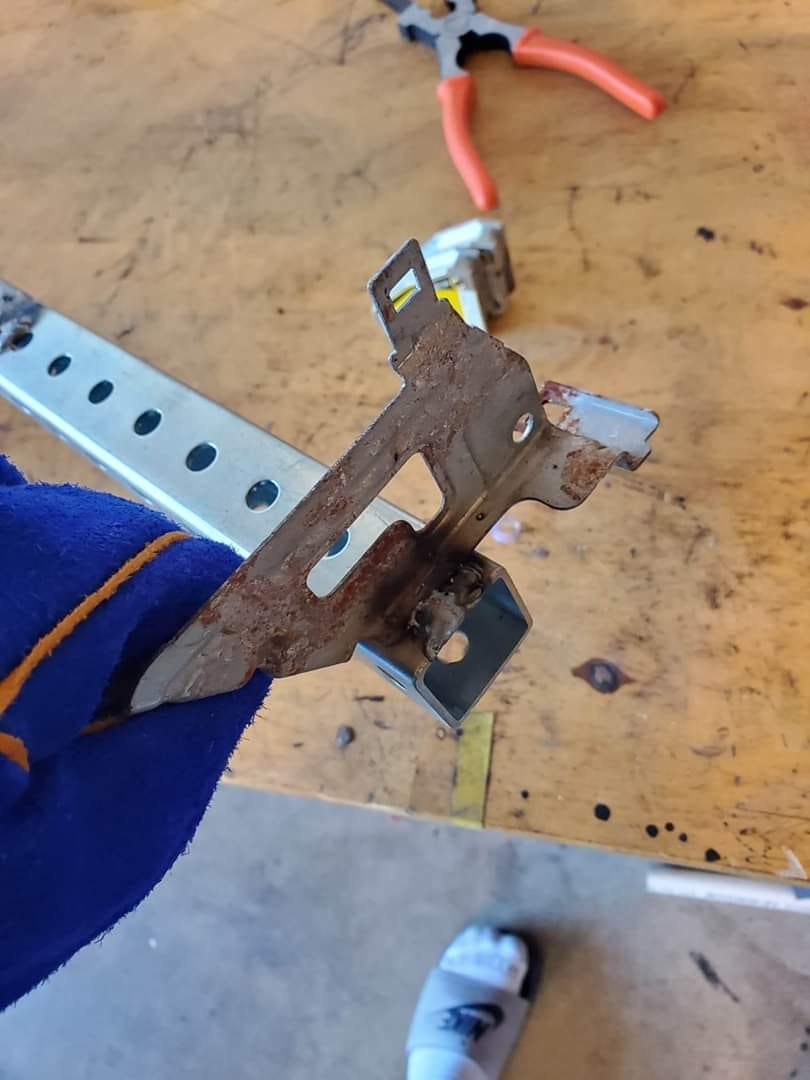

Here’s some random metal I found in my garage. Can I weld zinc coated steel? Not sure. I hope so.

Fortune favors the bold.

Look. It made some sparks and noise and left this behind. Let’s try to join something now.

GUYS SHORT SLEEVES AND CARGO SHORTS WAS A BAD IDEA

But nonetheless, I am a welder now.

I welded the back side and then took a hammer to it to see if the welds would break. They didn’t! Thanks for following along. I’m going to go join every piece of metal in my garage now.

By the way, the links to tools and supplies in this post are sponsored Amazon links because why wouldn’t they be?